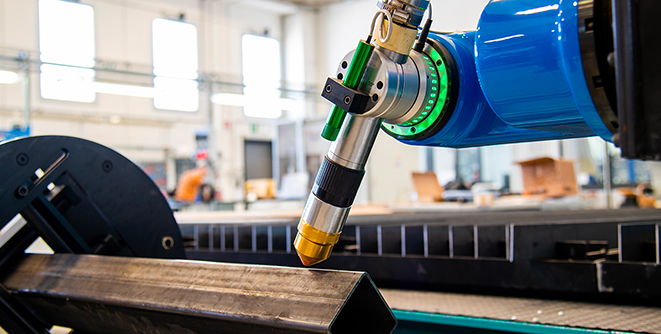

CNC

Motion planning

Revolution

XStar motion aims to radically innovate the motion planning of machine tools and robots. Its technology employs the implementation of optimisation algorithms and computational power to plan the movement of each machine in order to exploit its full power and update it for each individual task, autonomously.

Motion planning

Motion planning is the generation of the time-varying profile of each machine axis to carry out a given operation such as, for example, a cut or a weld or simply a movement of the tool. This process is based on three key steps:

• The tool path is generated starting from a digitisation of the result to be obtained - for example the drawing of a component;

• Transition from tool path to the path of each axis;

• Defining the motion of the machine - the speed at which each axis must follow the path assigned to it.

If the first two phases - in most cases - allow a solution with minimal freedom of choice, due to tolerances on the path that are binding for the processing in question, which are today the prerogative of CAD/CAM software, the third phase can produce very different machine behaviours depending on the techniques used, and the management of the trade-off between cycle time, how long will take the machine to complete the given path, determining the cost of the operation, and movement smoothness, less stress and less vibrations increase the life of the machine and improve the quality of the work.

Good indicators of the smoothness are the acceleration and acceleration variation values - jerk - which must be generated by the axes to execute the motion that has been planned. Lower acceleration and jerk values indicate a smoother motion, while higher values can lead to a 'jerky' motion, inducing vibrations and structural stresses and increasing the risk of premature wear of mechanical components.

The old way, heuristics-based approach

The state of the art is largely based on heuristics, i.e. rules that decide a priori at what speed - and therefore acceleration and jerk - a given path is followed. The path is usually divided in portions performed with predefined speed profiles, typically trapezoidal. In order to obtain acceptable cycle-times, the movement of the axes is typically not very fluid, or in order to respect the limits of the axes they produce excessively high execution times. To overcome this problem, the trajectory obtained following the application of the predefined speed profiles is filtered before being used in the machine, losing guarantees.

Pro:

Cons:

The XStar way

XStar motion exploits the full computing power available today and opens up new scenarios for motion planning and control. XStar motion technology is based on numerical optimisation algorithms. In particular, the problem of planning the motion of a machine along a given path in minimum time can be formulated as an optimisation problem with a unique solution. This solution, which provides the motion of the machine, is determined with efficient and reliable algorithms. The speed, acceleration, and jerk limits of the axes can be included in the problem as constraints, obtaining a motion that respects them.

Main advantages:

Why now?

Today it is possible to adopt numerical optimisation in machine control for two main reasons: firstly, the computational power available at reasonable costs allows optimisation routines to be performed with frequencies compatible with the operation of the machine; then modern convex optimisation approaches allow addressing problems relevant to high-speed machining.