XStar motion develops and provides optimisation based algorithms for motion planning in order to increase the productivity, achieve a better product finish and reduce the mechanical stress of the machine's components.

Our technologies are based on XSolve motion planner component. It represents a versatile technological solution designed to optimise machining operations on CNC machines and robots.

Using XSolve it is possible to evaluate the optimal trajectory, at minimum time, over a working-cycle path fulfilling the machine's velocity, acceleration and jerk limits.

What makes XSolve particularly interesting is its ease of use and its flexibility in implementation. In particular:

• does not need to set parameters for each task;

• needs, as parameters, only machine's limits and path tolerance error;

• is integrable on both robots and CNC machines;

• works online, providing the optimised references at the controller frequency;

• handles paths of arbitrary length.

Its implementation is made simple through the use of a set of dedicated API functions, that offers users various options to integrate this technology into their operational environments.

XSolve can be released in three different modalities

Power your application linking XS-lib directly with your software, getting all the advantages provided by XS-Solve. XStar Solve lib is a binary library powered by XSolve technology designed to compute optimised motion planning problems quickly and efficiently. It is linkable to all applications, and compatible with linux or Windows 32 and 64 bit applications. With a simple, well-documented API, it can be integrated quickly into customized applications, reducing development time and enhancing operational outcomes. It is recommended to install the library on devices capable of supporting high computational loads.

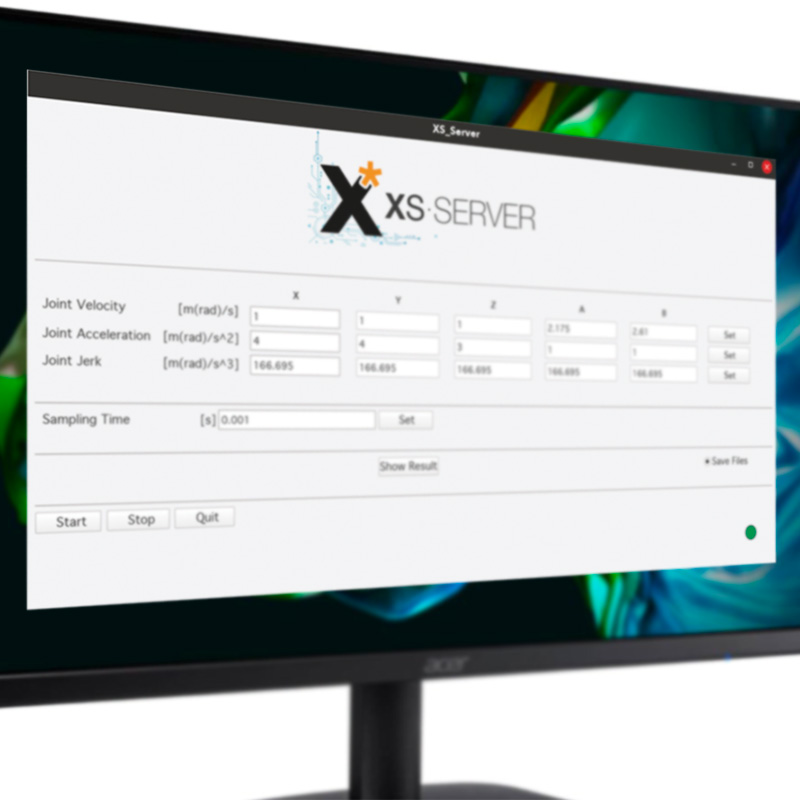

XS-Server is a Windows/Linux application that allows to use XSolve technology as a background running server. It is an advanced solution designed to compute optimal machine's trajectories both in real-time and offline, minimizing cycle time, improving machine performances and getting a better finishing quality of the worked piece. The application can be installed on the CNC or on an external hardware with respect to the client, making the installation flexible. If used on a separate hardware, it does not require the client to have a high performing device, making possible the integration of the XSolve technology on a huge variety of controllers. A simple set of dedicated API functions will make easy the integration with your system, enabling the communication between server and user.

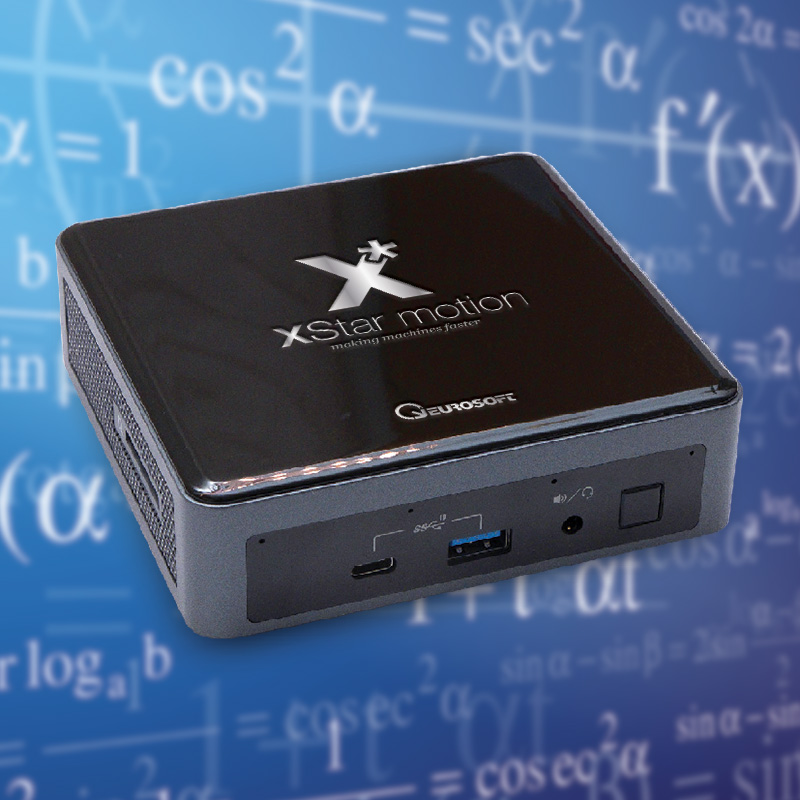

XS-Box is a dedicated computer unit that allows to use the XSolve technologies thanks the pre-installed XS-server application. It is the fastest way to integrate our algorithms to your machine, since it is a plug&play solution and doesn't need server installation on your controller. You just need to include the XS-API functions to your project to enable the communication with the server and get optimised motors references. This solution is particularly suitable for revamping. In its G-Code optimiser mode it doesn't require any hardware and software modification of the existing machine system, giving a file that can be directly processed by your controller, if compatible with G-Code files. A simple user interface will show the few parameters to be set, allowing to modify the machine's kinematics limits. The solution runs online and for infinite cycles.

↓

↓

↓

↓

↓

↓